Swivel Hoist Rings are an excellent choice for lifting or moving machinery, workpieces, and other heavy objects. In this video, we'll dive into the different components of a swivel hoist ring, how they function, and why they're a better option compared to other lifting points. Make sure to watch until the end for crucial safety tips!

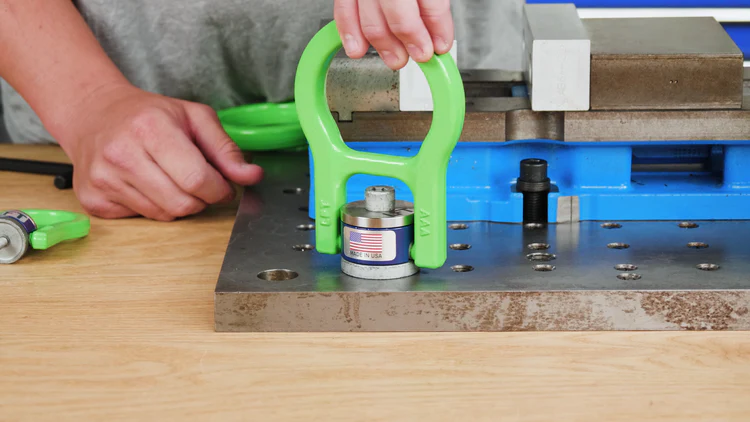

Understanding the Anatomy of a Swivel Hoist Ring

A swivel hoist ring consists of several load-bearing components that work together to ensure safe and reliable lifting operations.

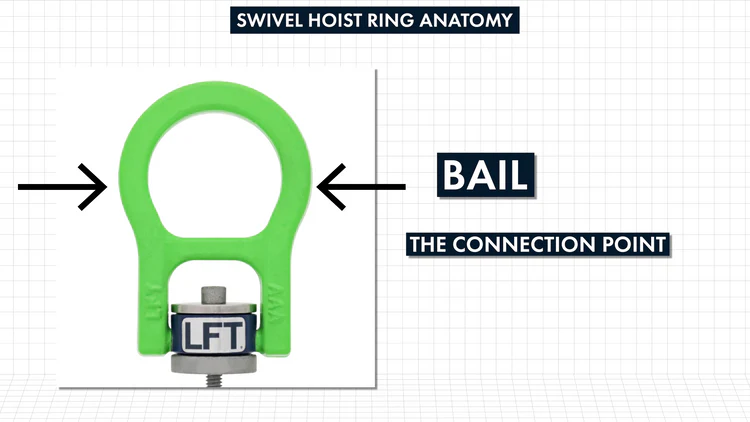

First, let's discuss the 'bail'. The bail is drop-forged for strength and acts as the connecting point. Any lifting equipment attached to the bail must fit snugly within the opening to prevent jamming. The bail features protruding lugs that lock securely into the body for smooth pivoting action.

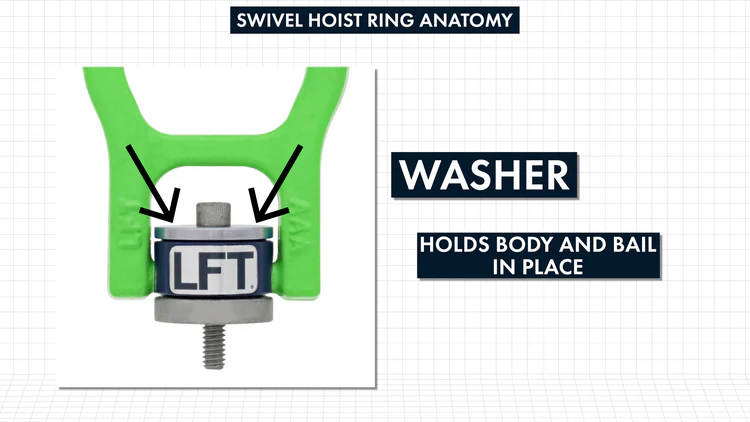

The body rotates around the bushing and is held in place by the load-bearing washer. Slight clearances are designed into the body to allow free rotation once the hoist ring is tightened to the correct torque specifications.

The washer keeps the body and bail securely fastened after the bolt is tightened. It also displays critical product data such as part numbers, serial numbers, rated load capacities, and recommended torque values.

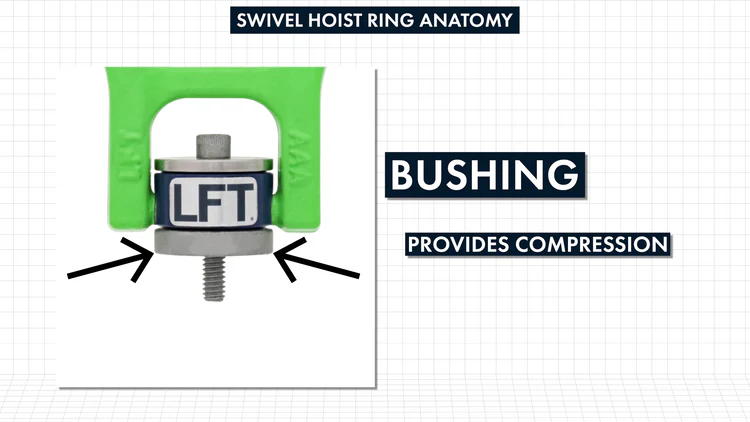

The bushing provides necessary compression to the object's surface, enabling the hoist ring to rotate freely without loosening during the lift. The bushing is designed with a broad base to support up to 100% of the rated capacity for inline loads and up to 90-degree angled loads.

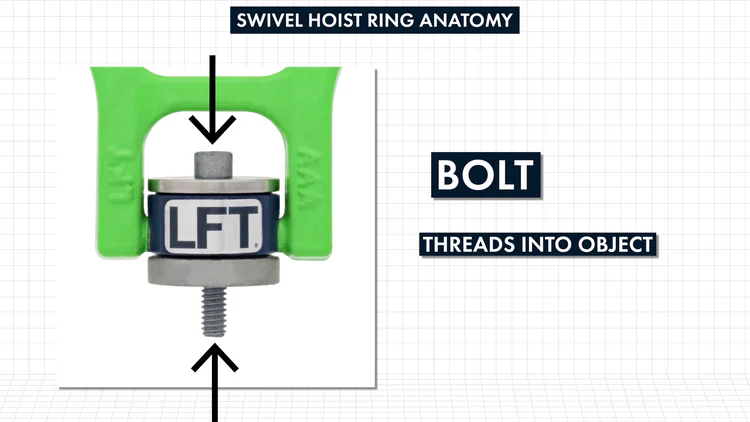

The bolt ensures sufficient holding power when torqued correctly, allowing the hoist ring to rotate freely without loosening during the lift. Thread engagement of the bolt must be at least 1.5 times the bolt diameter. Torque values are clearly marked on the hoist ring and are intended for clean, dry threads.

How Swivel Hoist Rings Operate

Swivel hoist rings function as versatile lifting points that offer multidirectional articulation, making them ideal for complex lifting tasks.

Since the bolt, bushing, and washer create tension and compression, they're rated for 100% of the working load capacity across the full range of the hoist ring's ability to pivot and rotate, provided the swivel hoist ring isn't obstructed.

It's important to note that swivel hoist rings are not meant to rotate under load. Instead, the term "swivel" refers to their ability to pivot and rotate during the initial loading process. This self-alignment capability creates an unobstructed in-line load path for the rest of the rigging setup.

Comparing Swivel Hoist Rings to Other Lifting Points

Traditional lifting points, such as machine eyebolts, are limited in their functionality because their load capacity decreases significantly at different angles of attachment. Swivel hoist rings, on the other hand, can handle a wide range of lifting applications and aren't as restricted by angled loads.

Conventional hoist rings may provide some flexibility but can only operate on a single plane of motion. Unlike these conventional designs, swivel hoist rings offer multidirectional movement along various axes, making them perfect for complex lifting scenarios like multi-leg lifting.

Moreover, swivel hoist rings boast greater compatibility with various connection components, including safety hooks, chain slings with multiple legs, web slings, round slings, wire rope slings, and soft ropes. If you require a hoist ring capable of turning and aligning to different angles while minimizing stress on lifting assemblies, swivel hoist rings are undoubtedly the best choice.

Ensuring Swivel Hoist Ring Safety

Proper installation of swivel hoist rings is essential since incorrect installation or misuse can result in lift failures and hazardous working conditions.

Regular inspections of all hoist ring components for signs of wear and damage are mandatory. Additionally, the torque requirements for the bolt should be checked periodically as bolts can loosen over time with extended use.

When installing swivel hoist rings, always tighten the bolt to the manufacturer's specified torque values. Adhering to these guidelines ensures the correct tension on the bolt, enabling the hoist ring to operate at its full stated working load capacity.

Avoid inserting washers or spacers between the bushing and the surface of the object being lifted. The bushing of the hoist ring should make full contact with the surface of the lifted item.

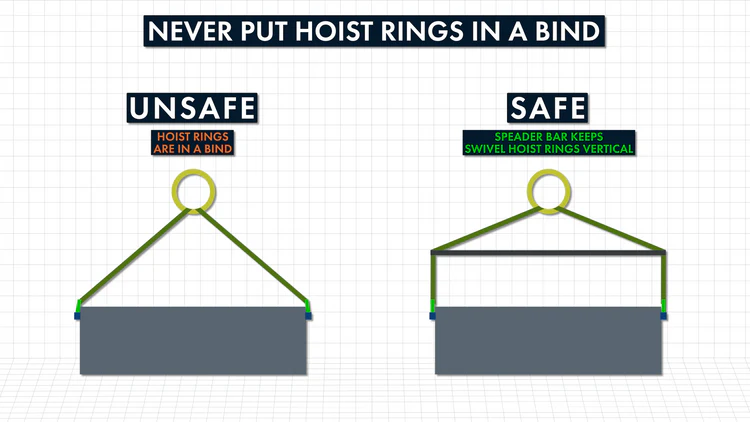

It's crucial to prevent your swivel hoist ring from becoming obstructed. Using spreader bars if necessary will help avoid the bail from binding against the workpiece and ensure even load distribution.

For more detailed information on swivel hoist rings, check out our comprehensive Hoist Ring Guide. I hope this gives you a solid understanding of swivel hoist rings and their advantages. Let me know if you have any questions or need further clarification!Bamboo Charcoal Board,Bamboo Charcoal Veneer,Bamboo Charcoal marble sheet,Bamboo Charcoal Wall Wand Panel

Linyi Dongtai Decoration Materials Co., Ltd , https://www.dongtaiwood.com